|

|

The veneer sheet

on the underside of a plywood panel, corresponding in thickness, and often in

species, to the face veneer on the upper or exposed surface. Its grain runs

parallel to the grain of the core, and crosswise to the grain of the

cross-banding.

|

|

BIRD'S EYE

|

Due to local

sharp depressions in the annual rings, accompanied by considerable fiber

distortions. Once the depressions are formed succeding

growth rings follow the same contour for many years. Rotary veneer cuts the

depressions crosswise, and shows a series of circlets called bird's eyes. It

occurs only in a small percentage of Maple trees.

|

|

BLISTER

|

Produced by an

uneven contour of the annual rings. The veneer has the effect of being

blistered. Must be cut rotary or half-round.

|

|

BOOK MATCHING

|

Achieved when

successive veneer leaves in a flitch are turned over like the pages in a book

and are glued in this manner. Since the reverse side of one leaf is a mirror

image of the succeeding leaf the result is a series of pairs. Individual

panels can be matched this way, or you can achieve this look over many panels

by sequence matching the panels. Book matching is the most common match. A

common problem in book matching is when the “tight” and “loose” sides are

matched and reflect light and stains differently. This may yield color

variations in some species which may be minimized by proper finishing

techniques.

|

|

BROKEN STRIPE

|

A modification of

ribbon stripe, the markings tapering out and producing a broken ribbon. If

the log described in ribbon stripe also has a twist in the grain the stripes

are short or broken.

|

|

BURL VENEER

|

Produced from a

large, wartlike growth on the trunk of the tree.

The grain pattern typically resembles a series of eyes laid side by side.

Obviously the veneers leaf sizes are generally small and additionally are

defective. While producing beautiful patterns, Burl veneer is difficult to

work with.

|

|

BUTT MATCHING

|

Achieved when

veneers are matched as described for book matching but the ends of the sheets

are also matched. At times, the veneer being used is not long enough to cover

the desired panel heights. In this case the veneer leaves can also be flipped

end for end and the ends matched.

|

|

|

A grain

appearance characterized by a series of stacked “V” and inverted “V”. Pattern

common in plain-sliced (flat-cut) veneer.

|

|

CENTER MATCHING

|

Each panel face

is made with an even number of flitch sheets with a center line appearing at

the midpoint of the panel and an equal number of veneer sheets on each side

of the center line. The number of leaves on the face is always even, but the

widths are not necessarily the same.

|

|

CHECKS

|

Small slits

running parallel to the grain of wood, caused chiefly by strains produced in

seasoning.

|

|

CORE

|

There are four

types of core construction used in plywood panels: a) Lumber Core: Consists

of a heavy core of sawn lumber between crossbands.

The thick center core permits doweling, splining

and dovetailing. b) Veneer Core: Method of plywood construction consisting of

3, 5, 7 or more plies of veneer laid with grain direction of adjacent plies

at right angles to each other. c) Particle Board: This type of core consists

of chips or flakes of resign-coated wood fused together under heat and

pressure to form a core for plywood. D) Medium Denisity Fiber Board a more

refined panel with a process similar to that of Particle core.

|

|

CROSS BREAK

|

Separation of the

wood cells across the grain. Such breaks may be due to internal strains

resulting from unequal longitudinal shrinkage or to external forces.

|

|

CROSS FIRE

|

Figures which

external across the grain as mottle, fiddle-back, raindrop and finger-roll

are often called cross figure or cross fire. A pronounced cross fire adds

greatly to the beauty of the veneer.

|

|

CROSSBAND

|

The veneer sheet

between the core and the face veneer. Its grain runs at right angles to the

grain of adjacent layers, thereby providing the remarkable stability of

hardwood plywood.

|

|

CROSSBAR

|

Type of figure or

irregularity of grain resembling a dip in the grain running at right angles,

or nearly so, to the width of the veneer.

|

|

CROTCH VENEER

|

Produced from the

portion of the tree just below the point where if forks into two limbs. The

grain is twisted, creating a variety of flame figures. Often resembling as

well formed feather. The outside of the block produces a swirl figure that

changes to full crotch flame figure as the cutting approaches the center of

the block.

|

|

CURLY

|

Found mostly in

Maple or Birch, and is due to the fibers being distorted and producing a wavy

or curly effect in the veneer.

|

|

CUT MARKS

|

A raised or

hollowed cross grain cut caused generally by a nick in the knife.

|

|

|

Checks, splits,

open joints, knotholes, cracks, loose knots, wormholes, gaps, voids, or other

openings interrupting the smooth continuity of the wood surface.

|

|

DIAMOND MATCH

|

This is generally

done with a straight grain veneer. If a rectangle is divided into 4 quadrants

the veneers match at an angle to the quadrant line, and the grain forms a “V”

at these lines. The result is a diamond shape formed by the grain directions.

|

|

DISCOLORATIONS

|

Stains

in wood substances. Common veneer stains are sap stains, end stains, blue

stains, stain produced by chemical action caused by the iron in the cutting

knife coming in contact with the tannic acid of the wood, and those resulting

from the chemical action of the glue.

|

|

|

The

better side of any plywood panel in which the outer plies are of different

veneer grades.

Also

veneer spliced to a certain pattern and cut to exact size.

|

|

FIDDLE BACK

|

A fine, strong,

even, ripple figure as frequently seen on the backs of violins. It is found

principally in Mahagony and Maple, but occurs

sometimes in other woods.

|

|

FIGURE

|

The pattern

produced in a wood surface by annual growth rings, rays, knots, deviations

from natural grain such as interlocked and wavy grain, and irregular

coloration. Appears across the grain. Mottle, fiddleback

and raindrop are often called cross figure or cross line.

|

|

FLAKE (RAY)

|

Flake figure is

developed only in those species which have very heavy medullary

ray growth, specifically Oak, Lacewood, and

Sycamore. When the saw or knife cut is directly on or near to the radial, it

is close to parallel with the medullary ray and

therefore develops the "Flake" effect.

|

|

FLAT CUT

|

Also called Plain

Slicing, is the most common method of veneer manufacturing, producing a grain

pattern known as cathedral. Because each leaf in the flitch is similar, a

consistent and even matching pattern is possible. Flat cut veneer is ideally

suited for wall panels and furniture.

|

|

FLITCH

|

a) A

section of a log made ready for cutting into veneers.

b) After

cutting, all bundles are laid together in sequence as they were sliced.

|

|

|

Size and

arrangement of the cells and pores of the living tree. Grain is not

synonymous with figure. Woods fall into three groups: Fine grained (Birch,

Cherry, Maple, etc), medium grained (Walnut, Mahogany, etc.) and coarse

grained (Oak, etc.). Coarser grained woods can usually be cut to develop a

more conspicuous pattern.

|

|

|

Similar to rotary

peeling, also producing a high veneer yield. Used primarily to add width to

narrow stocks by increasing the plane of cut. Also used to enhance a

particularly wild grain pattern. Matching is possible because the leaves can

be kept in sequence. Half round cutting may be used to achieve "flat

cut" veneer appearance.

|

|

HARDWOOD

|

General term used

to designate lumber or veneer produced from broad-leafed or deciduous trees

in contrast to softwood, which is produced from evergreens or coniferous

trees.

|

|

HEARTWOOD

|

The nonactive center of a tree generally distinguishable from

the outer portion (sapwood) by its darker color.

|

|

HERRINGBONE

|

Veneer strips are

used and matched to both sides of the center line, at an angle. The resulting

appearance is reminiscent of the bones of a fish as they are attached to the

back bone.

|

|

HOLES, WORM

|

Holes resulting

from infestation of worms.

|

|

|

The line between

the edges or ends of two adjacent sheets of veneer or strips of lumber in the

same plane.

|

|

|

Sound knots 1/4

inch or less that do not contain dark centers. Inconspicuous or blending pin

knots are barely detectable at a distance of 6' to 8', do not seriously

detract from the overall appearance of the panel, and are permitted in all

grades.

|

|

KNOTS, OPEN

|

Opening produced

when a portion of the wood substance of a knot has dropped out, or where

cross checks have occurred to produce an opening.

|

|

KNOTS, SOUND,

TIGHT

|

Knots that are solid across their face and fixed by growth to

retain their place.

|

|

|

The process of

gluing pr bonding the component sections of the plywood into a single

permanent unit stronger than the original wood itself.

|

|

LONGWOOD

|

The trunk of the

tree is the part that begins just above the stump and continues to just below

the crotch, most veneers are cut from longwood by

quarter, rotary, or flat cutting.

|

|

LOOSESIDE

|

In knife-cut

veneer, that side of the sheet that was in contact with the knife as the

sheet was being cut. The bending of the wood at the knife edge causes cutting

checks.

|

MATCHING

OF BURLS, CROTCHES, STUMPS

|

Because of their

generally exotic grains, these wood figures need special treatment when being

matched into faces. Burls and crotches in particular have a tendency to be

buckled. In the process of making a panel face, the veneer needs to be

flattened and patched if needed. They also have a tendency to develop fine

hairline splits, so must be carefully handles in further manufacturing. This

extra labor and care adds to the expense of using these grains, but the

results are usually well worth the cost.

|

|

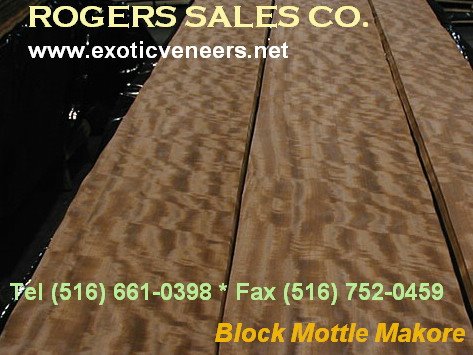

MOTTLE

|

A variegated

pattern which consists principally of irregular, wavy fibers extending for

short distances across the face. If there is also some irregular cross figure

in a log with twisted interwoven grain, the broken stripe figure becomes a

mottle.

|

|

|

A panel composed

of small particles of wood and wood fiber that are bonded together with

synthetic resin adhesives in the presence of heat and pressure.

|

|

PECKY

|

Pockets of

disintegrated wood caused by localized decay, or wood areas with abrupt color

change related to localized injury such as bird peck. Peck is sometimes

considered as a decorative effect such as bird peck in pecan and hickory pr

pecks in cypress.

|

|

PLY

|

A single sheet of

veneer, or several pieces laid with adjoining edges,

which form one layer in a piece of plywood.

|

|

PLYWOOD, HARDWOOD

|

A panel composed

of an assembly of layers or plies or veneer ( or

veneers in combination with lumber-core, particleboard-core, MDF-core,

hardboard-core, or of special core material) joined with and adhesive. Except

for special constructions, the grain of alternate plies is always

approximately at right angles, and the face veneer is usually a hardwood

species.

|

|

|

This cut requires

the largest diameter logs and produces straight grained veneers. The quarter

slicing of oak can result in the appearance flake.

|

|

|

(Mismatched) A

panel having the face made up of specially selected dissimilar (in color and

grain) veneer strips of the same species and generally V-grooved at the

joints between stripes to simulate lumber planking.

|

|

REVERSED DIAMOND

|

This is commonly

done with a straight grain veneer, a rectangle is

again divided into 4 quadrants. The grain direction is from the center point

to the outside edge in each quadrant. The resulting appearance is that of a

series of "Vs" formed by the grain match at joint line pointed in

at the center point.

|

|

RIBBON STRIPE

|

Result of quarter

slicing a log and the appearance actually is between broken stripe and plain

stripe. It gives the general appearance of a ribbon sometimes slightly

twisted.

|

|

RIFT CUT

|

Produced by

cutting at a slight angle to the radial to produce a quartered appearance

without excessive ray flake. The Rift cut method, commonly used for Oak, can

only be used on sizable logs. Rift Cut veneer can easily be sequenced and

matched.

|

|

ROPE

|

If the twist in

the grain of broken stripe is all in one direction a rope figure results.

|

|

ROTARY PEELING

|

The log is turned

in a circular motion against a knife peeling off a continuous thin sheet of

wood veneer (like unrolling wrapping paper), the most economical method of

producing veneer, resulting in the highest yield. The grain is inconsistent

and leaves are most difficult to match. This type of veneer is best suited

for paint grade or utility surfaces.

|

|

ROUGH CUT

|

Irregular shaped

areas of generally uneven corrugation on the surface of veneer, differing

from the surrounding smooth veneer and occurring as the veneer is cut by the

lathe or slicer.

|

|

RUNNING MATCH

|

The panel face is

made from components running through the flitch consecutively. Any portion of

a component left over from a face is used as the beginning component or leaf

in starting the next panel.

|

|

|

This is the outer

portion of the tree. As additional layers of growth accumulate on the outer

perimeter, the inner layers of the sapwood becomes

heartwood. Sap is lighter in color and the differentiation in color and

thickness of the sap layer varies considerably by species.

|

|

SLICED

|

Veneer produced

by thrusting a log or sawn flitch into a slicing machine which shears off the

veneer in sheets.

|

|

SLIP MATCHING

|

Means that veneer

leaves in a flitch are "slipped". Successive veneer leaves in a

flitch are "slipped" one alongside the other and edge-glued in this

manner. The result is a series of grain repeats, but no pairs. The danger

with this method derives from the fact that grain patterns are rarely

perfectly straight. Sometimes a grain pattern "runs off" the edge

of the leaf, a series of leaves with this condition could usually make a

panel - "look like it is leaning". In book matching the pairs

balance each other.

|

|

SOFTWOOD

|

General term used

to describe lumber or veneer produced from needle and/or cone bearing trees.

|

|

SPECIES

|

A distinct kind

of wood.

|

|

SPLICED FACE

VENEERS

|

Face veneers that

have been joined together in any one of several matching effects through the

careful factory process of tapeless slicing.

|

|

SPLITS

|

Separations of wood

fiber running parallel to the grain.

|

|

STREAKS, MINERAL

|

Natural

discolorations of the wood substance.

|

|

STUMP VENEER

|

Produced from the

base of the tree. Here the grain pattern is always swirly

twisted and often accompanied by cross fire and patches of burl. The sizes

are normally small.

|

|

|

In knife-cut

veneer, that side of the sheet that was farthest from the knife as the sheet

was being cut and containing no cutting checks (lathe checks).

|

|

|

A thin sheet of

wood, rotary cut, sliced, or sawn from a log or flitch. Veneering goes back

to the early days of the Egyptians, about 3,500 years ago. Down through the

years and cultures veneering ahs enriched furniture and architectural

interiors with sheets of rare and beautiful woods bonded to other plain,

sturdy wood based substraights to form a panel.

|